Comprehensive Material Testing Lab: Your Companion for Exact Quality Assurance

Looking Into the World of Product Screening and Evaluation

Product testing and analysis plays a crucial function in many sectors, from making to building. It involves a methodical evaluation of different products to establish their buildings, performance, and dependability. By using a series of techniques, such as destructive and non-destructive examinations, professionals have the ability to discover valuable understandings regarding the actions and qualities of products. Furthermore, the devices utilized in material screening have developed dramatically, enabling scientists and designers to obtain a much deeper understanding of the products they collaborate with. In this discussion, we will check out the value of material screening, delve right into typical strategies and devices, go over applications across sectors, and highlight emerging fads that are shaping the future of this area.

Value of Material Testing

Product screening is a crucial element of the design and manufacturing industries, guaranteeing the high quality, reliability, and safety and security of materials used in various applications. The significance of material testing can not be overemphasized, as it plays a pivotal role in assuring the performance and durability of structures and products.

One of the main factors for conducting product testing is to examine the mechanical residential or commercial properties of materials. This consists of determining their stamina, toughness, elasticity, and solidity. By subjecting products to numerous mechanical tests, designers can properly evaluate their viability for specific applications and ensure they meet the needed specs and standards.

An additional important element of material testing is the recognition of possible defects or flaws. By utilizing non-destructive screening strategies such as ultrasonic testing or aesthetic examination, makers can discover any flaws that could endanger the structural integrity or capability of the materials. This assists in preventing expensive failures, mishaps, and possible obligations.

Furthermore, material testing additionally enables for the analysis of material habits under various ecological conditions. Variables such as temperature, moisture, and corrosive environments can dramatically influence the performance and life expectancy of materials. By subjecting them to environmental testing, designers can examine their resistance to such problems and make notified decisions concerning their suitability for specific applications.

Typical Methods in Product Evaluation

Various techniques are commonly utilized in the evaluation of products to establish their buildings and attributes. These methods play a vital duty in comprehending the habits and performance of products in various applications. One of the most common strategies is microscopy, which enables researchers to envision the microstructure of products at different ranges. Optical microscopy provides a macroscopic view, while electron microscopy offers higher resolution and can expose atomic-scale information.

Another commonly utilized strategy is spectroscopy, which entails the interaction of materials with electro-magnetic radiation. As an example, infrared spectroscopy can recognize the functional groups present in a product, while ultraviolet-visible spectroscopy can determine its optical residential properties. X-ray diffraction is another effective method that permits researchers to evaluate the crystal framework of materials and determine their phases.

Thermal evaluation is also typically utilized to study the thermal behavior of materials. Differential scanning calorimetry, for example, can identify the melting point and warm ability of a material, while thermogravimetric evaluation can gauge its weight-loss as a feature of temperature.

Furthermore, mechanical screening is essential to recognize the mechanical residential or commercial properties of products. Techniques such as tensile testing, solidity screening, and effect screening offer useful details about a product's durability, stamina, and tightness.

Tools Used in Product Testing

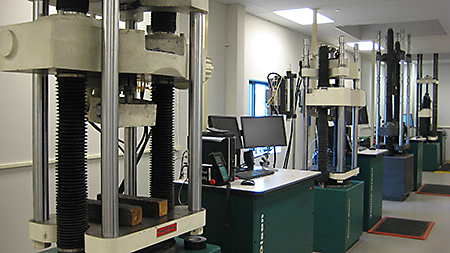

An array of specialized instruments and devices is employed in product screening to accurately assess the properties and habits of various materials. These devices are vital for carrying out experiments and getting trusted information in various markets, consisting of aerospace, auto, construction, and production.

One of the most common devices made use of in material screening is the global testing maker (UTM) click One more essential tool is the solidity tester, which determines a product's resistance to impression or infiltration.

Furthermore, thermal analysis tools, consisting of differential scanning calorimeters (DSC) and thermogravimetric analyzers (TGA), are made use of to investigate the thermal buildings and habits of products, such as melting points, glass shifts, and decay temperatures.

Applications of Material Testing and Evaluation

To completely make use of the valuable information gotten with the use of specialized instruments and equipment in material screening, it is crucial to discover the variety of applications where this evaluation can be applied. Product testing and analysis play an important function in various industries, consisting of aerospace, automotive, construction, and manufacturing.

In the aerospace industry, product testing and analysis are used to make sure the security and dependability of aircraft parts. material testing lab. By subjecting materials to severe conditions, such as high temperature levels and stress, engineers can examine their efficiency and make educated choices regarding their viability for usage in airplane

In the automotive industry, material screening and analysis are utilized to improve the toughness and performance of vehicles. By reviewing the homes of different products, suppliers can create stronger and lighter elements, resulting in improved fuel efficiency and total lorry efficiency.

In the building and construction market, product testing and analysis are made use of to make certain the architectural stability of buildings and infrastructure - material testing lab. By examining the strength and toughness of building and construction products, designers can develop frameworks that can stand up to various lots and environmental conditions, ensuring the safety of passengers

In the manufacturing sector, read product testing and evaluation are vital for top quality control functions. By evaluating the residential or commercial properties of raw materials and finished items, manufacturers can recognize any issues or weak points, allowing them to make required renovations and supply top quality items to consumers.

Future Trends in Product Testing and Evaluation

Emerging technologies are reshaping the area of product testing and evaluation, reinventing the means sectors enhance the performance and review of materials. As modern technology continues to advancement, new trends are arising that are anticipated to even more enhance the capabilities of product screening and evaluation.

Among the crucial future patterns in material screening and analysis is using expert system (AI) and artificial intelligence (ML) algorithms. These modern technologies can assist in automating the analysis procedure, permitting faster and more precise outcomes. AI and ML can also aid in recognizing patterns and trends in big datasets, making it possible for scientists to make even more informed choices.

Another trend is the growth of advanced non-destructive testing (NDT) strategies. NDT approaches, such as ultrasonic testing and thermal imaging, are coming to be extra advanced, enabling the detection of flaws and problems in products without the requirement for destructive screening. This not only saves time and sources but also ensures the honesty of the checked materials.

In addition, there is a growing rate of interest Our site in nanotechnology and its effect on material screening and evaluation. Nanomaterials exhibit unique properties that vary from their bulk equivalents, and specialized techniques are being created to examine and define these products at the nanoscale.

Final Thought

In verdict, material screening and analysis is a vital aspect of various markets and research areas. As modern technology proceeds to breakthrough, future patterns in material screening and evaluation are expected to further enhance accuracy, efficiency, and technology in this field.